When we first met our customer this spring, we had no idea what kind of ride we were in for. After tuning an LS-swapped Square Body for him, he casually mentioned his plans to upgrade his 1972 Chevrolet C10 by swapping the aging 327 engine for an LS3. Fast forward a couple of months, and his vision became a reality—but not without a few twists and turns along the way.

Setting the Goal: A Two-Week LS3 Swap

Our goal was clear from the start: remove the 171 WHP 327 and Turbo 350 from the C10, and drop in a 2015 Camaro-sourced LS3 engine paired with a 6L80 transmission. The challenge? We told him we could get it to run in two weeks, a lofty goal without cutting any corners or sacrificing build quality.

It seemed straightforward enough. But as anyone in the custom car world knows, things rarely go according to plan.

The First Curveball: L99, Not LS3

When the engine arrived, we were hit with an immediate curveball: it wasn’t the LS3 we expected. Instead, the engine was an L99, which features a different set of components and includes GM’s Displacement on Demand (DOD) system. A quick chat with the customer revealed he still wanted to proceed with the LS3 setup, so we overnighted all the parts needed to delete the DOD and convert the L99 to a full LS3 spec engine.

Despite the hiccup, we pushed forward. Within days, the engine was ready, and we could continue with the rest of the build.

A Custom Build: More Than Just an Engine Swap

With the engine swap sorted, we dove into the rest of the build. Our customer had a vision for the entire truck, and we were more than happy to make it a reality. Here’s a rundown of the modifications we tackled:

- Dakota Digital Gauges: To give the C10 a modern touch and provide precise performance data.

- Under-Bed Fuel Tank from Holley: We removed the old in-cab tank and installed a new under-bed fuel tank to open up space and improve safety.

- 3.73 Positraction Rear Gears: With a set of 3.73 gears from Randy’s Ring and Pinion, the C10 gained even more performance and drivability.

- Air Conditioning System: We built a complete air conditioning setup to ensure that the truck would be comfortable, even on the hottest days.

- Custom Stainless Exhaust System: Our friends over at Hazel Dell Muffler helped us design and build a custom exhaust with Borla mufflers that not only sounds amazing but also performs great.

- Custom Driveline: I-5 Driveline worked quickly to fabricate a custom driveline, ensuring a smooth connection between the LS3 and the 6L80 transmission.

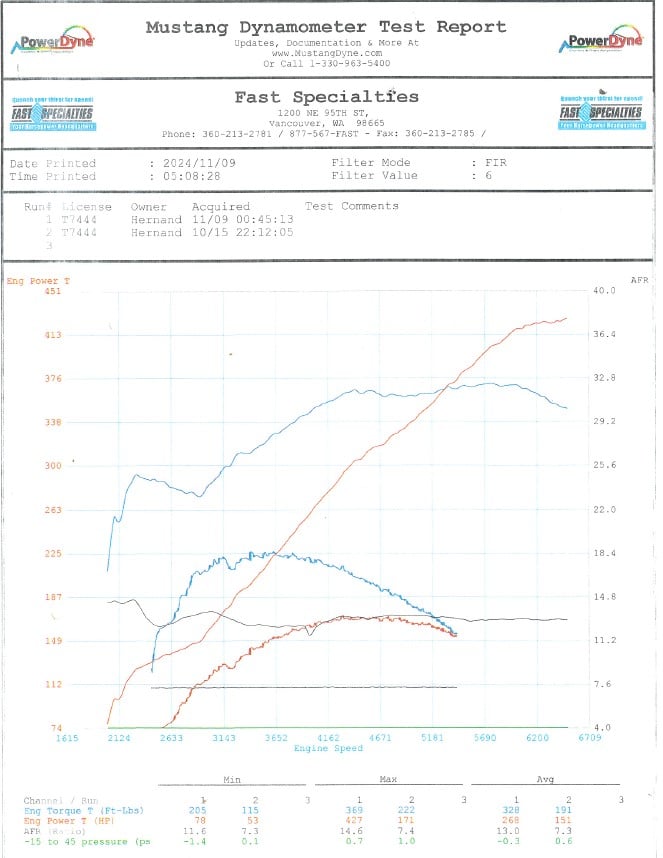

The Numbers: A 150% Increase in Horsepower

Once the build was complete, we brought the C10 onto the dyno to fine-tune the engine. The results were impressive: after tuning, the truck was putting down 427 horsepower to the wheels—a massive 150% increase in power from the original 327.

We had successfully achieved the goal: not only did we swap the old engine for a modern LS3, but we also enhanced nearly every other aspect of the truck to make it a true performance machine. Our customer was thrilled with the results, and the build was a massive success.

A Surprise Follow-Up: Another Project in the Works

The last surprise? The customer was so happy with the outcome of his C10 that he surprised us by dropping off his 1969 Chevrolet Chevelle for a supercharged LSA swap. The project had been in progress at another shop for nearly two years, and now it’s our turn to take the reins and finish what they started. Stay tuned for updates on this exciting new project!

Conclusion:

At the end of the day, what makes projects like this so rewarding is not just the technical challenge, but the satisfaction of seeing a customer’s vision come to life—especially when it exceeds expectations. From overcoming the unknowns that you run into when building a hot rod like the L99 engine swap to hitting that 427 horsepower mark, this C10 is a testament to what can be achieved with a little ingenuity, hard work, and a passion for performance.